FOR MOST AEROSPACE engineers, an explosion in a rocket engine is a disaster. But for Kareem Ahmed, it’s the entire point. As the director of the Propulsion and Energy Research Laboratory at the University of Central Florida, Ahmed has spent the past few years developing a next-generation rocket engine that uses controlled explosions to boost stuff into space. It’s called a rotating detonation engine, and it promises to make rockets lighter, faster, and simpler. But before it ever heads to space, engineers and physicists need a better understanding of how the hell it works.

“The challenge has been trying to understand what’s really happening inside and to be able to predict the performance,” Ahmed says. “We want to get them to the point where they are as predictable as a traditional engine.”

Rotating detonation engines, or RDEs, sound like something out of science fiction, but the concept is about as old as the space age itself. In the late 1950s and early ’60s, aerospace engineers working on rocket engines envisioned RDEs as a way to turn a problem into a solution. “Sometimes the rocket motors would get a real bad instability and you’d get an explosion,” pioneer Arthur Nicholls recalled in a University of Michigan interview shortly before his death. “Then it led to the idea—well, what if we use that?”

Everything you need to know about Blue Origin, SpaceX, Virgin Galactic, and what actually happens to your body if you go live in space.

RDEs are fundamentally the same as all other rocket engines: A fuel and oxidizer are ignited, and as they rapidly expand they are pushed out of a nozzle at high speeds, which blasts the rocket in the opposite direction. But the devil, as always, is in the details. In conventional liquid rocket engines like the kind used by SpaceX, the fuel and oxidizer are pressurized and fed into the ignition chamber using bulky turbopumps and other complicated machinery. A rotating detonation engine doesn’t need these pressurization systems, because the shock wave from the detonation provides the pressure.

See Also:- Virgin Galactic is partnering with NASA to develop supersonic point-to-point air travel

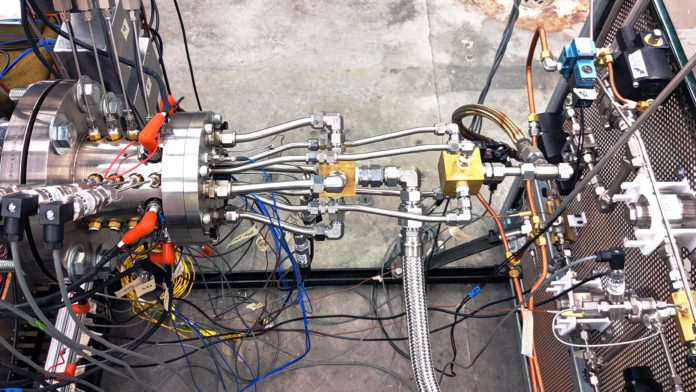

In the RDE developed by Ahmed and his colleagues, hydrogen and oxygen are fed into a combustion chamber. A small tube is used to send a shock wave into the chamber, which triggers the detonation. As the pressure wave moves through the chamber, it encounters more hydrogen and oxygen being fed into the front of the engine by dozens of tiny injectors. When the detonation wave hits the fresh fuel and oxidizer, it rapidly raises the temperature and pressure of the gases. This causes them to combust and send a flame shooting out of the rocket engine.

We’re accustomed to thinking of an explosion as a one-off event—something blows up and that’s that. But a functional RDE requires sustaining the initial detonation, which is where the “rotating” part comes in. The propellant is fed to the engine through a specially designed injection plate with dozens of small holes that act like a racetrack for the detonation wave, allowing it to rotate around the cylinder. The rotating wave feeds off new propellant and will generate new detonation waves in an endless loop until there’s no more fuel flowing into the chamber.

Earlier this month, Ahmed and a team of researchers from the University of Central Florida and the US Air Force published the test results from the first rotating detonation engine to use hydrogen and oxygen for propellant. This chemical cocktail is regularly used to propel the upper stage of a rocket on the final leg of its journey to orbit. But Ahmed says that many engineers believed this chemical mixture was too volatile to be used in a rotating detonation engine. “Hydrogen is a crazy fuel,” he says. “Most believed it wasn’t possible to detonate hydrogen and oxygen, because it would tend to deflagrate like a typical rocket engine, rather than a detonation motor.”Most Popular

The number of waves produced by the engine is determined by how much propellant is being pumped into the system. The engine built by Ahmed and his colleagues had five waves, but other RDEs have had up to eight. It’s still unclear how the number of waves affects the performance of the engine, which will require a better understanding of the waves themselves.

To study the waves produced by their engine, Ahmed and his colleagues added a chemical tracer into the propellant and filmed the engine using a high-speed camera rolling at over 200,000 frames per second. The result looks like a throbber, the spinning wheel on your PC that tells you when a computer application is hanging.

Ahmed estimates that eliminating all the turbopump machinery could reduce a rocket’s weight by around 30 percent. It’d also make the engine far less complicated and more fuel-efficient than a conventional one.

Harnessing explosions and riding them into space seems cool in theory, but it’s incredibly challenging in practice. The biggest challenge remains getting a grasp on the fundamental reactions that occur in the engine. “Most detonation wave phenomena appear to be poorly understood,” William Hargus, who leads the Air Force Research Laboratory’s rotating detonation engine research, wrote in a 2018 paper describing the program. He concluded that RDEs “require significant improvements in their fundamental understanding to determine whether they can provide performance improvements to the rocket propulsion community.”

See Also:-SpaceX, Blue Origin Will Supply NASA With Moon-Landing Equipment

But they are difficult to study because the detonation process is incredibly violent and “wicked fast,” says James Koch, an interim postdoctoral researcher in applied mathematics at the University of Washington. The initial detonation that ignites the motor creates a shock wave that travels up to 4,000 miles per hour across a distance of just a centimeter or so. And once the engine is started, it’s difficult to pick out the weak signal from the rotating detonation waves from the rest of the flame.

After an initial spate of research in the late 1950s and ’60s, the mounting complexities involved with controlling an explosion led NASA and other space agencies to focus their attention on improving conventional engines instead. Since then, research on rotating detonation engines has simmered in the background, and over the past few years the idea has come back into vogue. In 2018, officials at the Air Force Research Laboratory announced a program to develop and fly an RDE that used conventional rocket propellants. The engine developed by Ahmed’s team is a result of that program, and he says the Air Force is aiming for the first flight of an RDE engine by 2025.Most Popular

To overcome the challenges of working on RDEs, engineers rely on computational fluid dynamics to create detailed simulations of the detonation process. This is the same computing technique also used to design new planes, submarines, and rockets, but modeling a rotating detonation engine pushes a supercomputer to its limits. “It’s a very nitty-gritty, brute force approach,” says Koch. “The Department of Defense has been running simulations on rotating detonation engines that take on the order of three weeks to a month to run on their leading supercomputer.”

Koch was determined to find a better way to model the detonation waves, so he turned to a branch of mathematics called nonlinear waves and pattern dynamics, which uses math to create models that describe how patterns form. When Koch and his colleagues fired up a small rotating detonation engine they built in their lab, Koch found that the fundamental physical processes occurring in the engine could be described with his mathematical models—no supercomputer necessary. “This approach worked really well,” Koch says. “I can run a simulation on my laptop that takes maybe 30 seconds to produce results that are similar to what took the DOD three weeks.”

Koch says that his new technique is “making waves” in the research community, but that it isn’t likely to replace modeling via supercomputer anytime soon. It’s also still abstract in the sense that it can’t be used to model specific RDEs. Koch can’t just plug in the number of injectors, type of fuel, diameter of an engine, and other parameters and arrive at a simulation of a particular engine. “We’re years away from something like that,” he says. But this mathematical model is an important step toward understanding the fundamental physics of RDEs well enough to make it happen.

RDEs may have a lot more to offer than improved rockets. The US Department of Energy is investing in research on using RDEs for stationary power generation, and companies like General Electric are exploring their application to jet engines. But Ahmed says these systems will first be put to practical use in rockets because there’s so much to gain in reduced weight and fuel efficiency. After 60 years of effort, exploding rocket engines might be just about ready to blast off.

See Also:-SpaceX fail its Recent Star-ship prototype during a cryogenic test