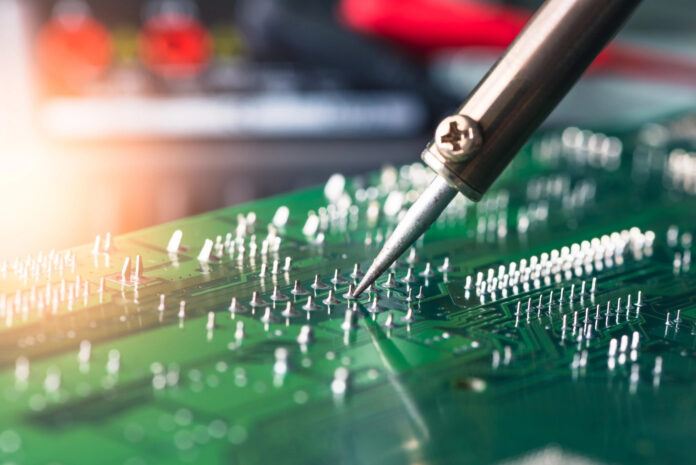

Printed circuit boards (PCBs), which perform essential functions in electronic devices, including displays and sensors, need a lot of energy to create. Moreover, traditional PCB manufacturing processes generate large amounts of liquid waste and high carbon emissions.

In any case, there are all the more harmless to the ecosystem approaches to delivering PCBs, including added substance-producing processes that utilize inkjet and laser printing, while completely biodegradable PCBs are likewise not too far off.

To get its cut of the $90 billion PCB fabricating pie, Tokyo-based startup Elephantech has fostered an eco-accommodating PCB called P-Flex, utilizing inkjet printing-based electronic circuit-producing innovation, which it says lessens fossil fuel byproducts by 77% and water utilization by 95% contrasted with regular cycles.

Also Read: Is there a website that teaches how to make circuit boards?

The fundamental change Elephantech introduces to the PCB cycle is that while electronic circuits are regularly made through purported “subtractive” fabricating, which includes layering a whole surface with metal prior to dissolving the regions that aren’t required, with Elephantech’s “unadulterated added substance” process, it just sets up metals where they are expected in any case. Nothing is hence eliminated (for example squandered).

The organization likewise says that its nanoparticle inkjet innovation assists cut costs by 32%, by eliminating various methodologies from assembling with processing.

The new capital, which brings its complete raised to roughly 7 billion yen ($50 million) since its beginning in 2014, will assist the startup with scaling its business from Research and development and its momentum creation volume, which is centered around its homegrown market, to universally target clients.